Summary:Many purchasing decisions hinge on this key question: Can the cable be integrated with standard connectors, or will specialized fittings be required?

Many purchasing decisions hinge on this key question: Can the cable be integrated with standard connectors, or will specialized fittings be required? This aspect not only impacts your initial cost but can also affect the efficiency of installation, operational reliability, and long-term performance of your electrical systems.

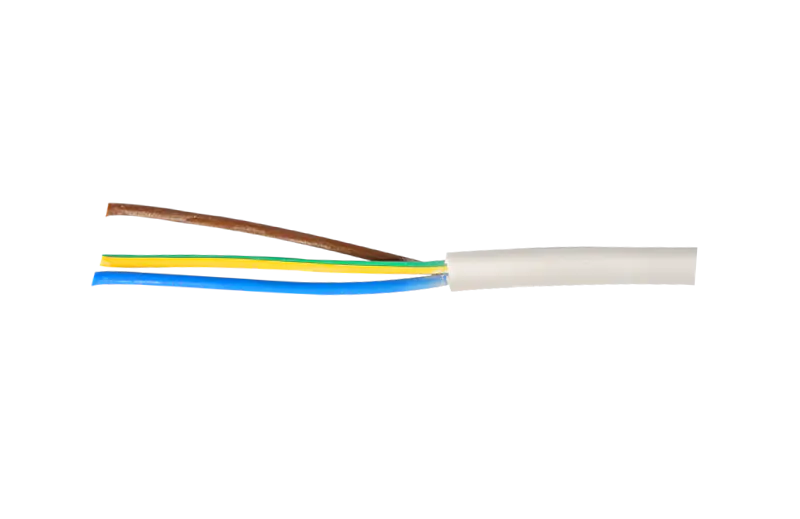

Most industries rely on specific connector standards, which can vary depending on the application, local regulations, and the type of electrical system in use. For example, industries like construction, manufacturing, or telecommunications often utilize common connector types such as spade terminals, ring terminals, or push-in connectors, which are designed to work with widely available cables. If your low-voltage power cable is engineered to fit these standard connectors, it can save both time and money by reducing the need for custom solutions and streamlining installation processes. However, it’s essential to verify whether your cable's conductor size, insulation type, and overall design are compatible with the most common connectors used in your sector.

In some cases, though, you might encounter specific applications or environments where more specialized connectors are required. For example, cables exposed to harsh conditions, like high moisture or extreme temperatures, may require connectors with enhanced sealing or protective features to ensure long-term safety and functionality. Additionally, certain industries, such as those dealing with sensitive or high-performance electrical systems, may demand connectors with higher precision or materials that resist corrosion or electrical interference. If your low-voltage power cable is designed to meet these higher standards, the required specialized connectors might come with an added cost, but they are necessary to ensure safety and optimal performance in such demanding applications.

Another consideration is the ease of obtaining these connectors. If your low-voltage power cable requires a unique connector type, it’s important to assess whether those connectors are widely available or need to be sourced from specialized manufacturers. The more common the connector type, the easier it will be to find a reliable supplier, reducing lead times and simplifying inventory management. On the other hand, if the cable demands uncommon fittings, you may face longer wait times or higher costs for custom components.

When evaluating compatibility, also keep in mind that some connectors are engineered for specific installation methods, such as crimping or soldering, while others may use screw terminals or push-fit designs. The compatibility of your low-voltage power cable with these various types of connectors can significantly impact installation efficiency. Additionally, understanding the long-term effects of connector choices on system reliability is crucial. Poorly matched connectors can result in issues like overheating, poor conductivity, or increased wear on both the cable and the connectors, leading to costly maintenance or replacements down the road.

Addressing connector compatibility early in the selection process can provide peace of mind and eliminate potential complications later. Understanding whether your low-voltage power cable works seamlessly with standard connectors or requires specialized components will help you make more informed decisions, optimize installation, and maintain system integrity over time.