Summary:Advancements in technology have profoundly transformed the manufacturing of low-voltage speaker cables, enhancing their performance, durability, and o

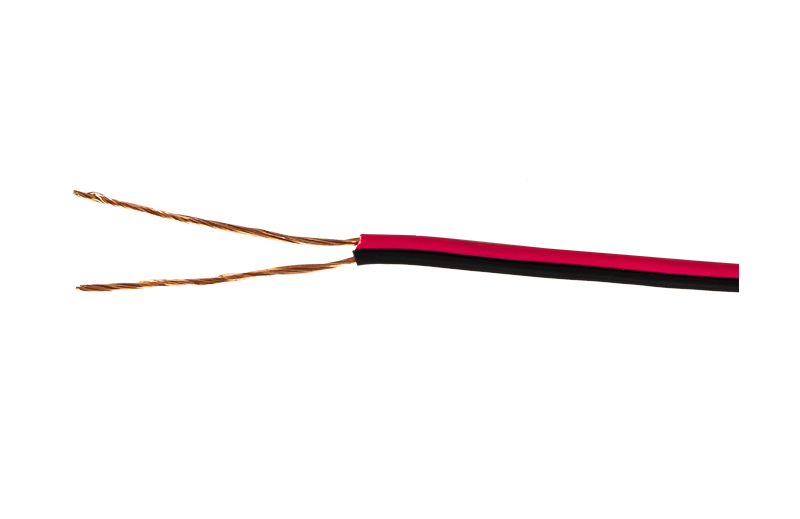

Advancements in technology have profoundly transformed the manufacturing of low-voltage speaker cables, enhancing their performance, durability, and overall functionality. In the past, speaker cables were primarily made from basic copper wire, which, while effective, had limitations in terms of conductivity and flexibility. Today, manufacturers leverage a range of materials and innovations to create cables that not only transmit sound more efficiently but also cater to the diverse needs of modern audio systems.

One of the most significant changes has been the introduction of higher-quality materials. While traditional copper remains the standard, many manufacturers now utilize oxygen-free copper (OFC), which has a higher conductivity and reduced oxidation potential. This results in a clearer signal and improved audio fidelity. Additionally, advancements in alloy technologies have led to the development of copper-clad aluminum (CCA) cables, which offer a lightweight alternative to pure copper while maintaining acceptable performance levels. These materials allow manufacturers to balance cost and quality, making high-performance options more accessible to consumers.

Insulation technologies have also evolved dramatically. The introduction of various types of protective coatings, such as PVC, Teflon, and even more specialized compounds, has greatly improved the durability and flexibility of low-voltage speaker cables. These advancements protect against environmental factors such as moisture, UV exposure, and physical wear and tear, thereby extending the lifespan of the cables. Furthermore, improved insulation materials can reduce interference from external electromagnetic fields, ensuring that the audio signal remains clean and undistorted.

The manufacturing process itself has benefited from technological advancements, particularly in automation and precision engineering. Modern manufacturing techniques allow for more consistent quality control, resulting in cables that meet stringent performance standards. Automated machinery can produce precise wire gauges and uniform insulation thicknesses, minimizing human error and variability. This level of consistency is crucial for maintaining sound quality across long runs of cable, particularly in complex audio setups where multiple connections are involved.

Moreover, advancements in design and engineering have led to innovations such as twisted pair configurations and braided shielding. These designs reduce electromagnetic interference and crosstalk, which are critical in maintaining audio clarity, especially in environments where multiple electronic devices operate in close proximity. By incorporating these advanced designs, manufacturers can offer low-voltage speaker cables that not only perform better but also fulfill the aesthetic preferences of consumers.

The rise of digital audio has also influenced the evolution of low-voltage speaker cables. As audio systems become increasingly integrated with digital technologies, the need for high-quality cables that can handle digital signals without degradation has grown. This has spurred manufacturers to create hybrid cables that can support both analog and digital signals, making them versatile for a variety of audio applications. Additionally, the push for sustainability has prompted manufacturers to explore eco-friendly materials and production methods, aligning with broader trends toward environmental responsibility in the consumer electronics industry.

Advancements in technology have fundamentally changed the landscape of low-voltage speaker cable manufacturing. From the materials used to the processes involved, these innovations have led to significant improvements in performance, durability, and versatility. As audio systems continue to evolve, manufacturers will likely keep pushing the boundaries of technology, ensuring that low-voltage speaker cables meet the demands of modern consumers and deliver the ultimate listening experience.