Summary:Industries that deal with oils, chemicals, or abrasive conditions need cables that can withstand more than just everyday wear and tear. The right insu

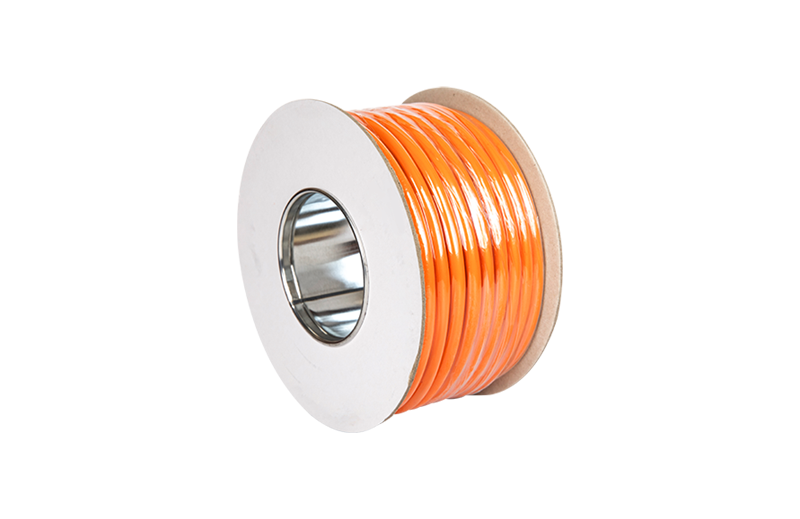

Industries that deal with oils, chemicals, or abrasive conditions need cables that can withstand more than just everyday wear and tear. The right insulation material ensures that the cables keep performing efficiently, maintaining safety, and reducing the risk of failure over time.

For environments exposed to oils, chemical spills, and extreme temperatures, you need insulation that’s up to the task. Specialized materials like PVC, XLPE (cross-linked polyethylene), and rubber compounds can be engineered to resist the degrading effects of oils and chemicals. These materials form a protective barrier that resists oil penetration, which can weaken standard cables and lead to premature failure. Whether it’s a factory floor with heavy machinery or an outdoor installation where the cables might come into contact with harsh chemicals, the insulation is designed to prevent damage and maintain its integrity, even when exposed to aggressive substances.

Abrasion resistance is another key factor for industries that require durability in environments where cables may be exposed to rough handling or physical wear. Insulation materials like thermoplastic elastomers (TPE) are excellent at resisting abrasion, and they can maintain performance even when cables are subjected to constant friction. This is particularly useful in areas where cables are installed along floors or exposed to movement, like in construction sites or automotive applications. With these materials, you won’t need to worry about constant replacements or repairs—your cables are built to last.

It's also important to consider how these insulation materials handle varying temperatures. Extreme heat and cold can cause many materials to crack or degrade, but modern insulation compounds are designed to handle a broad range of temperatures. This makes them perfect for industrial applications where cables are constantly exposed to temperature fluctuations, like in HVAC systems, outdoor equipment, or manufacturing plants with hot or freezing environments.

The insulation material used in low-voltage power cables can greatly impact the longevity and safety of your system. By selecting cables with the right insulation for your specific needs—whether it’s chemical resistance, oil protection, or abrasion durability—you ensure that your operations remain safe, efficient, and reliable for years to come.