Summary:The current-carrying capacity of low-voltage power cables is one of the most critical factors to consider during the design and installation of electr

The current-carrying capacity of low-voltage power cables is one of the most critical factors to consider during the design and installation of electrical systems. This capacity—also known as ampacity—determines the maximum amount of electrical current a cable can safely carry without risking damage to its insulation, overheating, or even failure. The relationship between a cable's current-carrying capacity, its size, and the ambient temperature around it is both complex and fundamental to ensuring the safety and efficiency of electrical systems.

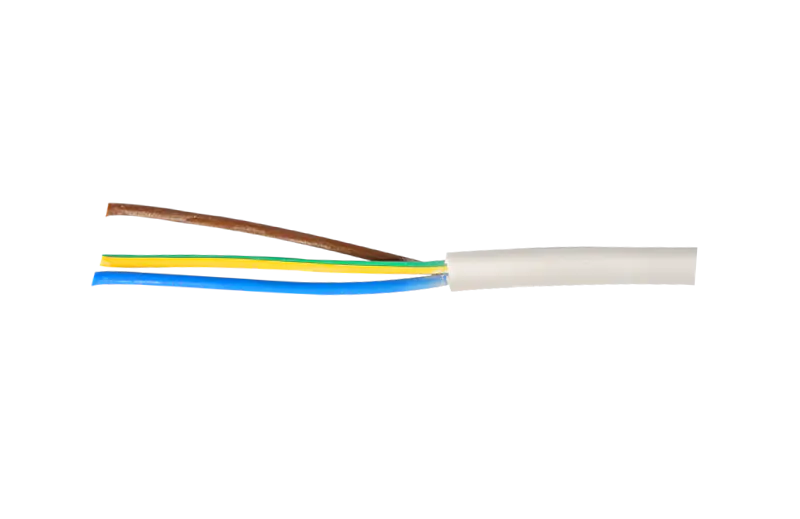

When selecting a low-voltage power cable, one of the first decisions is the size of the cable. The size primarily refers to the cross-sectional area of the conductor, which is typically measured in square millimeters (mm²) or American Wire Gauge (AWG). A larger conductor has more surface area, which allows it to carry more current without generating excessive heat. The key principle here is that the resistance of the conductor directly impacts how much current it can carry—larger cables have lower resistance, and therefore, they produce less heat for a given amount of current. However, the relationship between cable size and current-carrying capacity is not linear. Doubling the cable's cross-sectional area doesn’t necessarily double the amount of current it can handle. This is because other factors like insulation, material composition, and the construction of the cable also influence performance.

However, the cable size alone is not enough to determine the overall current-carrying capacity. Ambient temperature plays a crucial role as well. When cables are installed in environments with higher temperatures, they tend to heat up faster, which can lead to insulation breakdown and increased resistance. This makes it even more important to select the right cable size and insulation material for specific conditions. As the temperature rises, the cable’s ampacity decreases, meaning it can safely carry less current. For instance, a cable rated to carry 100A at 20°C may only safely handle 80A or 90A at 40°C. This reduction in capacity is crucial for preventing overheating and ensuring the system remains safe and functional over time.

The temperature coefficient of the cable insulation is another important factor to consider. Insulation materials such as PVC, XLPE, or rubber all have different thermal properties. For instance, cross-linked polyethylene (XLPE) insulation can withstand higher temperatures than standard PVC. In practice, engineers use ampacity derating factors to account for these temperature effects. These factors are typically provided by the cable manufacturer or in industry standards like the National Electrical Code (NEC) or IEC guidelines. By applying the appropriate derating factor, an engineer can adjust the nominal current-carrying capacity of a cable based on the expected ambient temperature.

It’s also worth noting that the installation environment—whether underground, in conduit, or exposed to air—can influence the temperature of the cable. Underground cables, for example, are often subject to higher thermal conductivity from the surrounding soil, which can either help or hinder the cable's cooling capacity, depending on moisture levels and soil composition. In contrast, cables installed in conduit or trays may face restricted airflow, causing them to heat up more quickly compared to cables installed in open air. Therefore, it's essential to factor in both the installation method and ambient temperature to accurately determine the cable’s safe current-carrying capacity.

To sum up, determining the current-carrying capacity of low-voltage power cables requires a careful consideration of both the cable size and the surrounding temperature. Larger cables generally allow for more current to flow without overheating, but temperature increases can reduce this capacity. Understanding these variables and applying the right temperature derating factors are crucial to ensuring the long-term safety and efficiency of any electrical system. By making informed decisions about cable selection and installation, professionals can avoid costly mistakes, prevent equipment failures, and ensure reliable power delivery in any environment.